The soap factories

Discover the history and know-how of the soap factories…

Le Serail

Marius Fabre

Alepia

Olive & Moi

La Licorne

La Savonnette Marseillaise

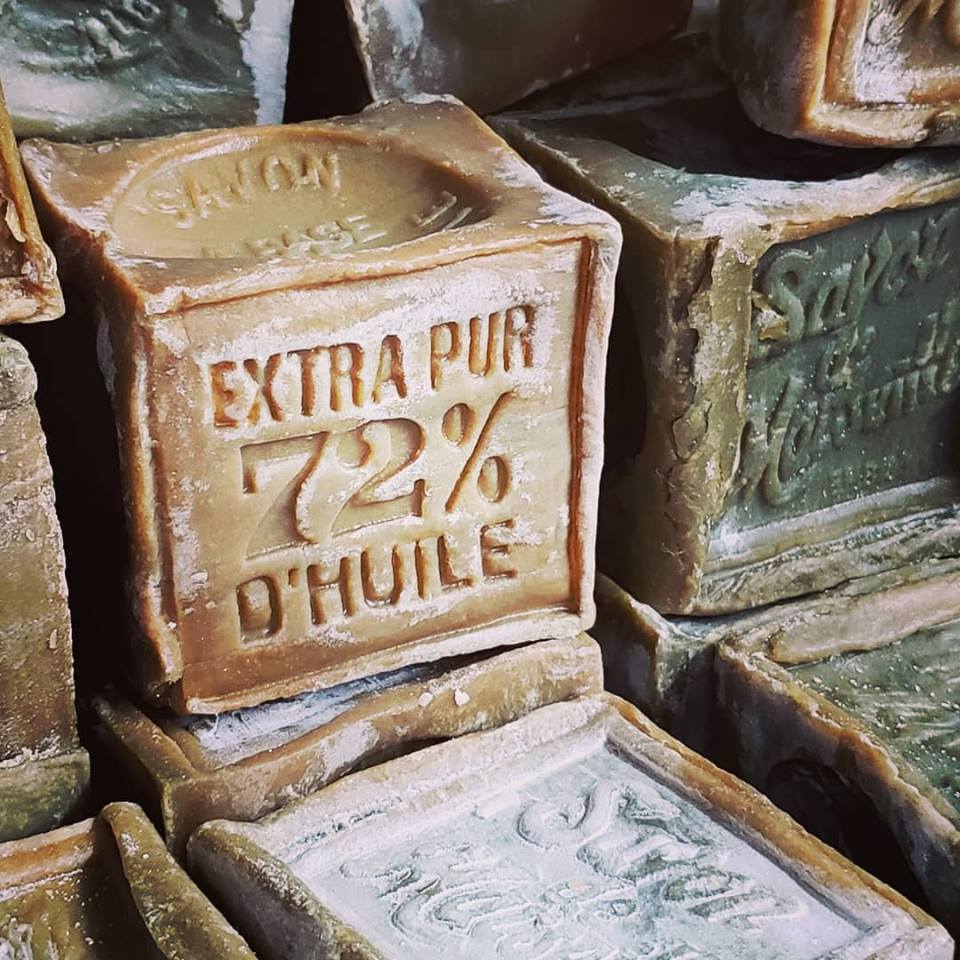

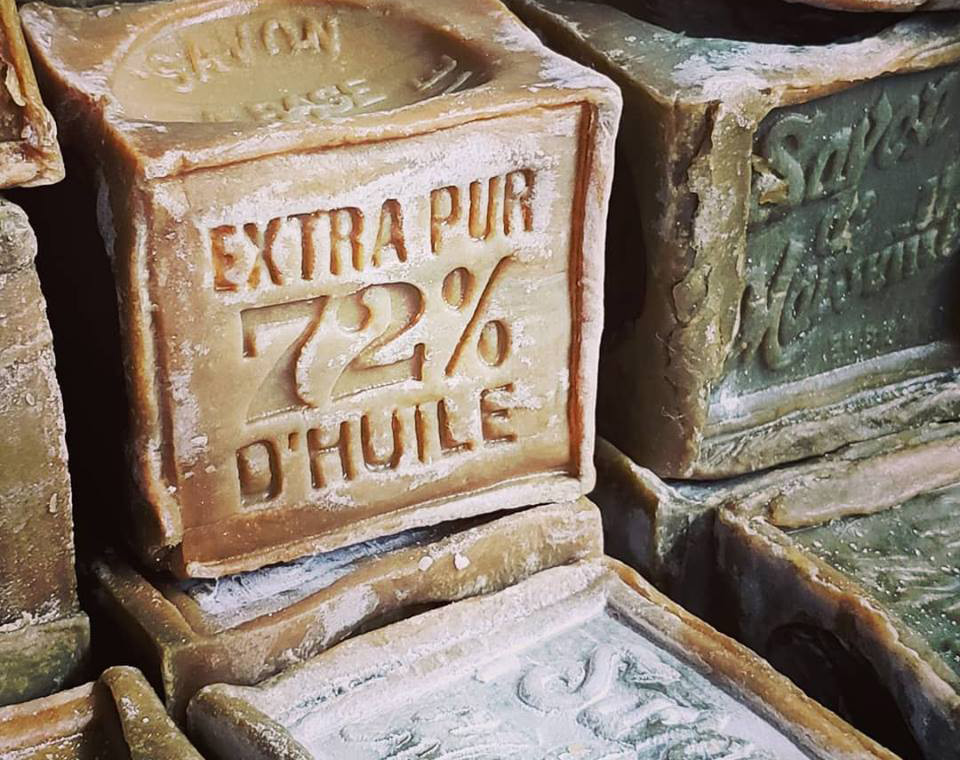

The Marseille manufacturing process

Authentic Marseille soap is made in a cauldron, using a specific saponification process, called the “Marseille process”, comprising 5 steps:

1. The pasting, or chemical reaction of saponification.

The mixture of washing soda and fatty substances of vegetable origin is heated and brought to a boil in the cauldron. It is gradually transformed into soap.

2. The release

Since soap is insoluble in salt water, this operation consists of adding a very dense salty detergent in order to drag the excess soda to the bottom of the cauldron. The soda “releases” i.e. it goes down to the bottom of the tank, the soap remaining above.

3. Cooking

This allows the complete transformation of fatty substances into soap by adding concentrated soda lye. It is an essential operation which explains the “proverbial longevity” of Marseille soap.

4. Washing

The soap paste is refined by washings, carrying away glycerol, impurities and unsaponified fatty acids.

5. Liquidation

A final wash with clear water brings the soap to its final state. Then floats the smooth and pure soap that makes the reputation of the Marseille process.

These different operations take about a week to ten days.