As you already know, Marseille soap is unique in the world. In addition to its history, its appellation contrôlée and its many advantages, its uniqueness lies above all in its manufacturing process. Do you know how these soaps are made?

The making

The manufacturing process is the same for all major soap factories such asLe Serail, Marius Fabre et La Savonnerie du midi.

14 days are necessary for the manufacture of real Marseille soap. Here are the different stages of production:

The cooked

- Saponification or pasting: transformation of oils into soap, under the action of soda or heat, in a large cauldron.

- Washing: the soap paste is washed several times in salt water to remove the remaining soda

- Cooking: the soap cooks for 1 day at a temperature of 120°C, under the supervision of the master soap maker

- Liquidation: several washes with water make it possible to have an “extra pure” soap, rid of all impurities

Finalization

- The casting of the cooked: the soap paste is then poured into gigantic molds

- Drying: the soap dries for 48 hours in the open air

- Cutting: once dry, the soap is cut into 35kg loaves

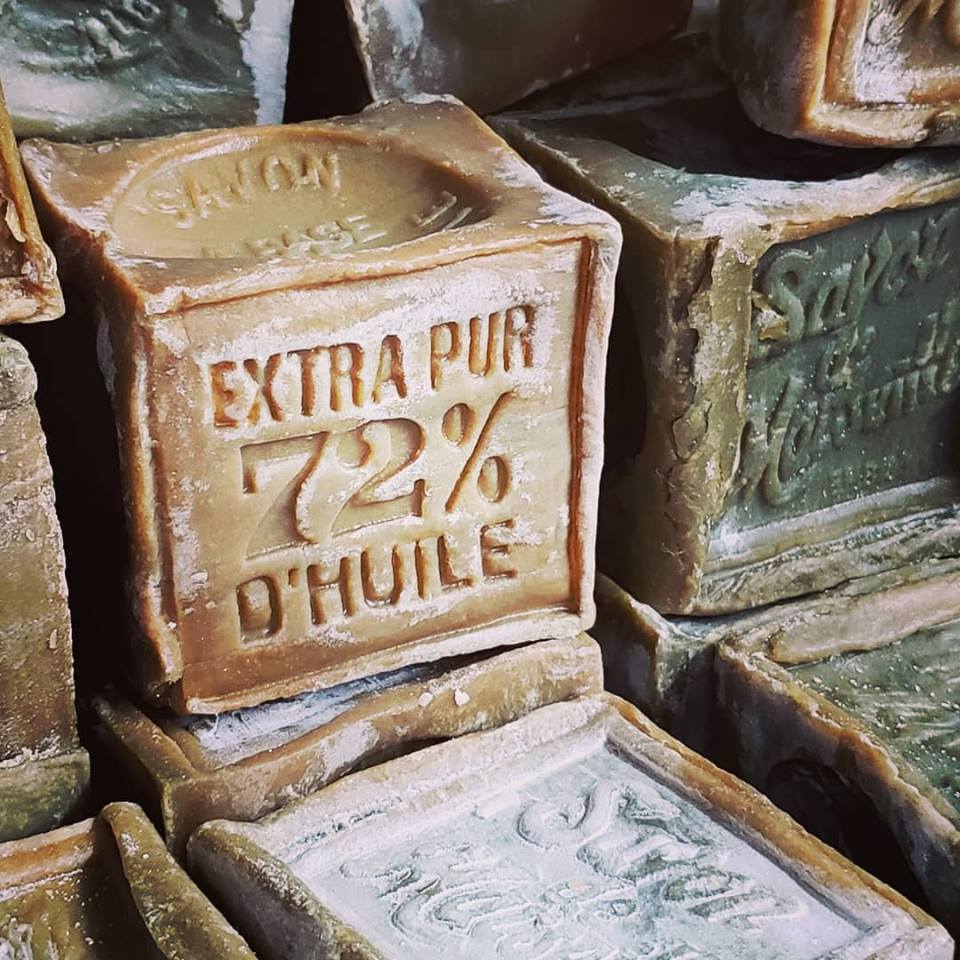

- Moulding: 2 types of marking=> hand stamped for bars or machine molded for cubes

- The stamping: on the 6 sides, which characterizes the real Marseille soap

It is a real unique traditional know-how in the world!